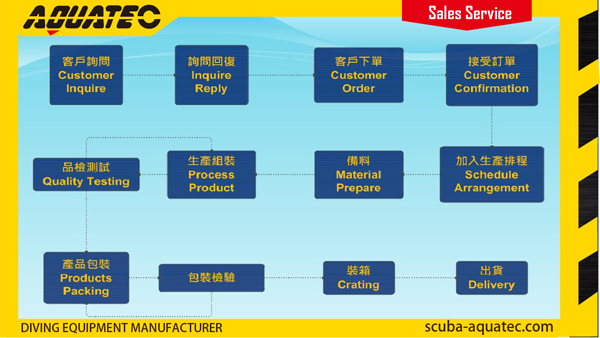

Process Flow

The production process is concerned with transforming a range of inputs into those outputs that are required by the market. Our production process involves a series of links in a production chain. At each stage value is added in the course of production.

1. Order confirmation

When customers place an order, this order is only an offer to buy from us. Please note that this purchase order is not to be considered as being final acceptance of your order by AQUATEC (Duton Industry Co., Ltd.) until we send E-mail to notifying an order confirmation. In other words, after AQUATEC (Duton Industry Co., Ltd.) received completely customers’ purchase order, an order confirmation contains information about detailing what you have bought, how much it cost and delivery/Shipping date, price(s)Notices, payment method, delivery and AQUATEC (Duton Industry Co., Ltd.) customer services contact information.... and etc. It is the responsibility of the both Customer to check the Order Confirmation sent by AQUATEC (Duton Industry Co., Ltd.), to ensure that the correct product with the correct price has been acknowledged. Also, AQUATEC (Duton Industry Co., Ltd.) needs to be contacted immediately to correct the order. The production schedule is carefully monitored section by section that is as an added value service to our customers. Order confirmation must be given within a reasonable period of time and in connection with the delivery of the goods at the latest. AQUATEC (Duton Industry Co., Ltd.) sales department, production management division will turn it into "production order" and establish process control time table, and then execute by production division and quality assurance division.

2. Schedule arrangement

To shorten customers’ waiting time for delivery, AQUATEC (Duton Industry Co., Ltd.) scuba diving production schedule management department have a comprehensive overview of the time schedule system. Generally speaking, the scuba diving production schedule management covers and including the strategy planning of production schedule, operation schedule, capacity management plan, work and shift arrangement in production. The major purpose is making the production schedule and tracking the production progress raw materials, manpower, equipment, and space in factory.

The productivity of multi-stage material handling system of AQUATEC (Duton Industry Co., Ltd.) depends not only on the parts stock safety, but also the entire production line arrangement to effectively control production plans of our scuba diving products and, so that delivery schedules can be reduced. Material requirements planning can also generate scheduling agreements for make-to-order production. The raw materials incoming time、manpower、equipment and space allocation will be planned and performed by production schedule management department that Identify opportunities at a glance to further optimize scheduling arrangements with our tracking system.

3. Parts receiving

All products parts are filed by AQUATEC (Duton Industry Co., Ltd.) management systems. The detailed parts list and parts version are clearly recorded for the best sales service efficiency. Part receiving process is to ensure that AQUATEC (Duton Industry Co., Ltd.) can meet the manufacturability and quality requirements of the supplied to the customer parts. In order to eliminate the possibility of parts missing or being taken by error, to Identification and traceability of scuba diving equipment parts and products information such as name, specification, part number, order number and current status, workers in the receiving or stocking department should understand the importance of inventory accuracy and the effect it has on the company to ensure they comply with the procedures to demonstrate that the established scuba diving equipment manufacturing process produces product that consistently meets all requirements during an actual production run.

Parts receiving employees must take to bring materials into the company and the transaction of parts into and out of stock and within departments such as scuba diving production. Specification requirements are properly understood by the parts receiving process, and that the manufacturing process has the potential to produce scuba diving product that will consistently meet these requirements during an actual production run at the quoted quantity. Its purpose is to define the approval process of new or revised parts, or parts that are from new or significantly revised production methods. Critical characteristics are features that have greater significance and most affect the outcome of a product or process of scuba diving equipment. So that the established manufacturing process has the potential to produce the part that consistently meets the all requirements during the actual production run, and to provide evidence that the customer engineering design record and specification requirements are clearly understood and fulfilled by AQUATEC (Duton Industry Co., Ltd.).

4. Fabrication

The production inspection process is followed with a "products inspection form" by AQUATEC (Duton Industry Co., Ltd.) that is to be checked item by item and signed by the same engineer who does the check, so that when performing after-sales servicing, the products past records can be easily traced.

As a scuba diving equipment provider, AQUATEC (Duton Industry Co., Ltd.) has the experience, equipment and size to handle every stage of the project. The manufacturing sector is closely connected with engineering and industrial design. Our manufacturing and diversification allows us to respond to project requests of all require quickly. Manufacturing is an arrangement whereby a first firm with specialized equipment processes raw materials or semi-finished goods for a second firm. Manufacturing process in which an item is made (fabricated) from raw or semi-finished materials instead of being assembled from ready-made components or parts. That helps speed up our project delivery and saves valuable time and money.

AQUATEC (Duton Industry Co., Ltd.) have grown into a diverse manufacturing business with a wide variety of equipment and highly skilled employees. We are experts in fabrication for several industries, and we continue to invest resources in new markets to help meet our clients' needs in the ever-changing manufacturing landscape. In addition, we offer a variety of services at competitive pricing. Our mission is to produce high quality parts, in a timely manner, at a competitive price for our customers. Our primary business is long and short-term contract manufacturing for a variety of customers.

5. Fabrication correction

AQUATEC (Duton Industry Co., Ltd.) provides valuable one stop service for the production of apparel products including suggestion of creating standard, scuba diving material, scuba diving accessory, secondary process, design, and pattern specification. Our management must approve the reconciliation of inventory discrepancies. Cycle counters or those tasked with maintaining the accuracy of the inventory may adjust the inventory database to correct discrepancies.

The major factors considered for the selection of materials include fabrication correction, which is grouped three distinct categories: essential correction, functional correction, and special correction. Essential correction is the limits of permissible deviation for the mechanical resistance and stability of the structure. Functional correction are the limits of permissible deviation for fit-up and appearance. Special correction is for Individual projects may specify special tolerances, either as a modification of the essential or functional tolerances or for aspects not already covered. AQUATEC (Duton Industry Co., Ltd.) would use quality assurance to ensure that a scuba diving product is manufactured in the right way, thereby reducing or eliminating potential problems with the quality of the final scuba diving product.

6. Quality inspection

AQUATEC (Duton Industry Co., Ltd.) Quality control inspectors make sure that scuba diving products meet standards of quality and safety. For example, they measure products, examine samples and test them, and accurately document the results of the inspections and testing to ensure operations and production quality.

AQUATEC (Duton Industry Co., Ltd.) Quality control inspectors rework or reject subassemblies or finished products as required. We make sure that everything from raw materials to finished products of scuba diving equipment meets quality and safety standards specified in the purchasing documentation. All scuba diving equipment production processes, whether large or small, requires elements of quality control and all inspection and testing is carried out to specified requirements. If a problem is identified, the job of a quality control team or professional might involve stopping production or service until the problem has been corrected. Final specification will be created, and scuba diving equipment production is started under quality control and delivery date management by the cooperation of related department development and production after the technical correction.

Furthermore, conduct and document process and system audits using written procedures as audit standards. Assembly and quality check process follows "quality control inspection regulation" to perform inspections of purchased scuba diving equipment parts, subassemblies or finished company products. The goal of the quality control team is to identify products or services that do not meet AQUATEC (Duton Industry Co., Ltd.) specified standards of quality.

7. Warehouse reception

AQUATEC (Duton Industry Co., Ltd.) warehouse is a large building where scuba diving goods are stored, and where they may be catalogued, and manufactured scuba diving goods are stored until shipped. The principal operation of the place is receiving, getting in new scuba diving products, and shipping out scuba diving products.

We utilize the most advanced technology and latest scuba diving equipment in our warehouse. These will not only bring increases order fulfillment speed and accuracy, but also eliminates shipping and receiving handling errors; moreover to decreases costs associated with under-utilized inventory resources, and to Improves inventory visibility and traceability.

AQUATEC (Duton Industry Co., Ltd.) warehouse maintenance of equipment used in the production process follow "facility and maintenance guidelines" can plan an annual or biannual physical inventory to count the entire inventory and adjust quantities to clean the system to prevent production process and after-sales service from being influenced by machinery fault. The discrepancies uncovered during a physical inventory also monitor the effectiveness of the cycle counting system and the inventory procedures.

8. Advance inspection

Advance inspection is part of quality assurance, which ensures that products are consistently produced and controlled to the quality standards appropriate to AQUATEC (Duton Industry Co., Ltd.) intended use.

Aquatec aims to accommodate any requests from customers based on our own technology of advanced inspection, material test and analytical inspection. Maintain all controlled document files and test records in a timely and accurate manner such as coordinate calibration of all test scuba diving equipment and fixtures, monitor critical scuba diving equipment and instrumentation to ensure proper operation and calibration, participate in the construction and revision of SOPs for the inspection function, put our product back in the product inspection, safety testing and recovery services for scuba diving function when a potential recall problem arises, assist in the writing and updating inspection scuba diving equipment procedures, protocol and checklists, evaluate problems and make initial recommendations for possible corrective action to supervise, work with production management and quality inspection to provide feedback to assemblers regarding accuracy of assembly procedures.

Advanced inspection has been achieved due to its own technology, know-how, and advanced facilities. Expert employees through the accumulation of experience have developed technical skills since the institution of AQUATEC (Duton Industry Co., Ltd.). All factories are able to provide high quality finished products while taking over responsibility and pride from the company history.

9. Delivery

Ordered products are delivered within the delivery date with comfortable quality after inspection which is along the demand of customer of AQUATEC (Duton Industry Co., Ltd.).

AQUATEC (Duton Industry Co., Ltd.) reserve the right to contact customers and arrange alternative delivery methods and timelines. Once our customers have received confirmation order, a unique order number will be communicated to our customers via invoice that can be used to track the status of your order; thus, we regret that no changes to the specified address and/or delivery option will be accepted.

To avoid products damage from transportation, AQUATEC’s standard export carton crate is five layered with Inner color box / blister, pack with 3-4 nylon straps supporting by technique to increase its loading strength. Every carton not exceeds 30 kgs for clients’ convenience transportation and storage.