Process Flow

Understand Scuba Aquatec's manufacturing process flow. From design concept and material selection to final QC, see how we ensure precision and quality in every step of dive gear production.

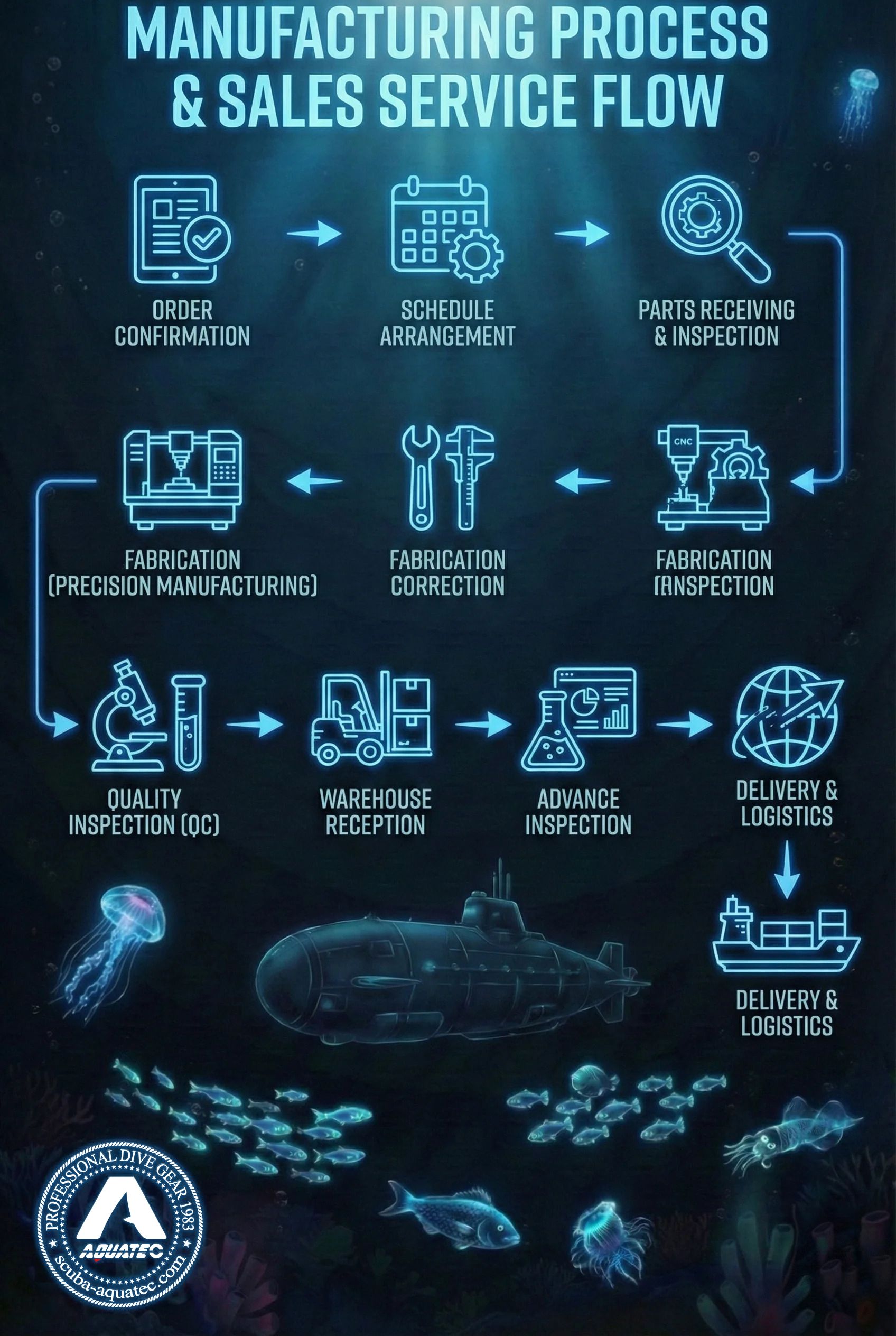

AQUATEC Scuba Gear Manufacturing Process & Sales Service Flow

Overview: SCUBA AQUATEC follows a rigorous 9-step manufacturing and sales process to ensure the highest quality diving equipment. From Order Confirmation and Precision Fabrication to Final QC & Delivery, our integrated production line guarantees reliability for global divers.

Order Confirmation

The process begins when an official Order Confirmation Email is issued by AQUATEC (Duton Industry Co., Ltd.). This document details the item list, costs, shipping dates, and payment terms. Once the customer verifies accuracy, our team converts it into an internal "Production Order" to establish a precise process control timetable.

Schedule Arrangement

To minimize lead times, we utilize a comprehensive scheduling system. This covers strategic planning of manpower, equipment, and raw material allocation. Our system optimizes workflow to ensure on-time delivery and effectively manages make-to-order production requirements.

Parts Receiving & Inspection

All incoming raw materials undergo strict inspection to ensure they meet manufacturability and quality specifications. We emphasize detailed traceability (part number, version, specification) to eliminate errors, ensuring every component used in our scuba gear meets the highest standards.

Fabrication (Precision Manufacturing)

AQUATEC handles all stages of fabrication in-house. We process raw materials into semi-finished goods using advanced CNC machining and engineering integration. A "Products Inspection Form" accompanies every batch, requiring engineer signatures to ensure full traceability for after-sales service.

Fabrication Correction

Our rigorous QA process allows for immediate Fabrication Correction if needed. This includes adjustments for mechanical resistance, structural stability, and cosmetic fit-up. Continuous monitoring ensures all products remain within strict project tolerances before moving to the next stage.

Quality Inspection (QC)

100% Quality Inspection is conducted on all finished products. Inspectors test samples against stringent safety standards documented in our purchasing specifications. If any issue is identified, production is halted for immediate correction, ensuring only defect-free equipment proceeds to packaging.

Warehouse Reception

Our warehouse utilizes advanced technology for cataloging and storage. This improves inventory visibility and accuracy, preventing handling errors. Regular physical counts and facility maintenance ensure that our machinery and stock are always ready for production or after-sales support.

Advance Inspection

For specific customer requests, we perform Advance Inspection using analytical testing equipment. This supports safety testing, potential recall management, and SOP revision. Our experts maintain accurate test records to guarantee consistent product quality across batches.

Delivery & Logistics

After passing final inspection, products are packed in 5-layered export cartons reinforced with nylon straps (max 30kg per carton). Each shipment includes a unique order number for tracking. We ensure secure and timely delivery to our global customers.

International Quality Standards

AQUATEC is committed to safety. Our manufacturing processes comply with rigorous international standards to ensure reliability underwater.

Frequently Asked Questions (FAQ)

Q: What is the standard lead time for production?

A: Our standard production lead time is typically 30 to 45 days after order confirmation. This may vary depending on order quantity and customization requirements.

Q: What warranty does AQUATEC provide?

A: AQUATEC offers a 1-year limited warranty against manufacturing defects for all our scuba equipment. We ensure that every product meets our rigorous quality standards before shipment.

Q: What is AQUATEC's quality control process?

A: We implement a multi-stage QC process, including material inspection, in-process fabrication checks, and a final functionality test before packaging to ensure CE-certified safety.

Q: Does AQUATEC offer OEM/ODM services?

A: Yes, we provide comprehensive OEM/ODM services, handling everything from design concept and prototyping to mass production and custom branding.

Q: How does the after-sales service work?

A: We offer full support including troubleshooting assistance, sending repair kits, or arranging return-to-factory services for maintenance.